Production technologies

- Rubber & PVC extrusion

- Foil & sheet coextrusion

- Injection moulding technology with inline compounding (also highly filled compounds)

- Hot-press & punching technology

- Microperforation & calendering of metal foils (aluminium, aluminised steel, stainless steel)

- Forming technology for metal foils

- Forming technology for floor coverings (TPO, tufting, needle felt)

- Friction welding

- Waterjet trimming

- PU moulded foam technology

- Injection moulding

- Heat deformation

- Aluminium and plastic extrusion

- Aluminium and zinc die casting

- Anodising and other surface treatments

- System assembly

- Metal working

Location Idar-Oberstein / Germany

Acquired on 01.02.2024, HAPPICH Innovation GmbH in Germany is a reliable partner for high-quality plastic injection molding and innovative solutions in plastics processing.

The servicesinclude:

- Plastic injection molding: Precise and efficient production of plastic parts according to individual requirements.

- Mold making: Specialized in the development and production of high-quality molds for the injection molding process.

- Plastics technology: Expertise in processing various plastic materials for a variety of applications.

- Injection molding technology: Advanced techniques and machines for precise and efficient injection molding.

Standort Adana / Turkey

On April 3rd, 2023 HAPPICH Otomotiv Ltd. has started a new production facility in Turkey, for the assembly of luggage rack and air-channel systems for buses and coaches.

HAPPICH Otomotiv - Adana plant:

- Production area of 2,250 m² with 9 assembly lines

- Annual production capacity currently 2,500 buses, expandable

The following services are offered on site:

- Design of extruded profiles

- Design and development of lighting systems

- Assembly of ceiling and side walls

- Assembly of luggage racks and air ducts

- Assembly of service sets

Location Herrstein / Germany

Acquired on 01.08.2019, HAPPICH Herrstein GmbH in Germany, manufactures body parts and exterior panels for agricultural, construction machinery, trucks and buses. Mostly large-area parts, they are manufactured from an unfilled thermoset in a P-DCPD-RIM process.

Processing Technology:

- RIM (Reaction Injection Molding) similar to casting.

- The use of lower pressure and lower molding temperatures, allow the usage of Aluminium Moulds.

- Specially purposed for small to medium series

Material is characterized by:

- Very high impact resistance, even at very low temperatures (-40/+60 °C)

- High process control and repeatability (Cpk Index)

- Very good bonding with most adhesives and Optimum paintability

Great freedom of design "Designer Friendly" for large and complex components (wall thickness variations, thread insert, etc.)

Location Velbert / Germany

At our production site in Velbert, Germany, we do:

- Profile production –extrusion of more than 5 million metres annually

- Production of acoustic insulations – customised acoustic insulations and heat shields for vehicle construction using the heat pressing process

- Assembly of low location lightings – finishing and assembly of LED-illuminated low location lightings for the marine industry

- Various assembly and trimming work (e.g. emergency exit hatches, hand straps)

Location Nýřany / Czech Republic

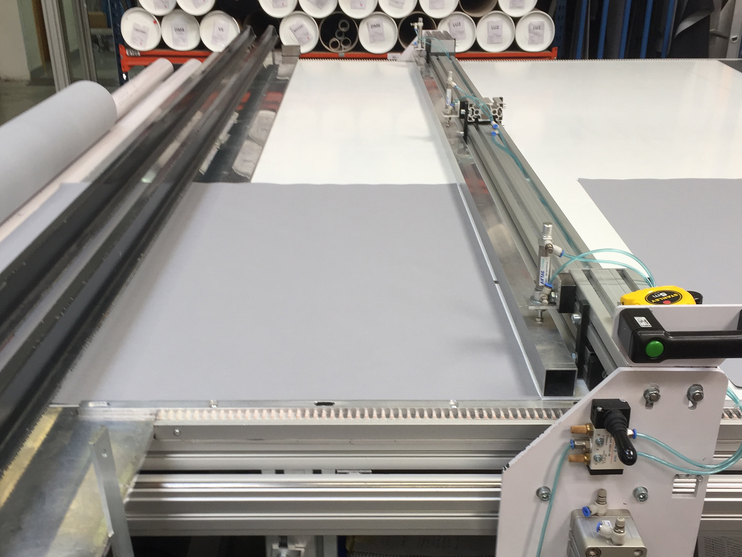

In 2016, HAPPICH GmbH launched its new production facility with one of the most modern extrusion lines at its new European site in Nýřany (near Pilsen) in the Czech Republic.

The following products are manufactured in Nýřany

- Impact sound insulation for floor coverings (PAPSILENT standard products and customised developments)

- Acoustic insulation foils for the automotive industry

- Acoustic insulation foils for buildings (walls, ceilings)

The material is a mineralically highly filled polyolefin foil which can be laminated with various foams and can be coated on one or both sides with different materials (e.g. aluminium vapour coated foil, fleece or adhesive coating) to achieve the desired effect.

Location Barcelona / Spain

In spring 2012 HAPPICH GmbH acquired 100% of the long-established Spanish supplier Auto Carrocerias Riu, Barcelona, with the brand Cowol. The newly founded Spanish company HAPPICH RIU S.A. produces the following:

- Standard modular roller blinds (also for small series) and for special applications, e.g. for panorama windows for trains

- Customised developments for mass production

- Other assembly work for locks and finishing

Location Redditch / Great Britain

Weston Body Hardware in Redditch, UK, founded in 1984 and acquired by HAPPICH in 2015, manufactures locking systems for cabin vehicles in the agricultural and construction sectors.

- Sheet metal handles – varnishing and surface coating

- Locks and handles for switch cabinets

- Locks and handles for generators and apparatus in the industrial sector

- Various locks for doors such as outward swinging door locks

- Various closures for flaps such as luggage compartment locks

- Accessories for closures such as actuators.

- Prototype construction

Location Zaragoza / Spain

Moldes Epila S.A.U., founded in 1992 and since June 2020 member of the Pelzer Family Company, focus its activities on the design, development and manufacture of special industrial machinery.

The following services are offered at the location in Zaragoza (Spain):

- Integrated design services using the latest technologies in design and simulation

- Technical advice on prototyping of product lines and industrial processes

- Construction of automated product lines

- Production and assembly of machines

- Robotization

- Transfer of machinery and complete lines to any place worldwide

- Accompanying the start of production

- Complete safety warranty in accordance with the standard safety guidelines.

Our focus is on the production of special machines for the automotive, aviation and industrial sectors.

MEI offers a wide range of machines:

- Manual and automatic mould carriers

- Mould carriers with air cushion lifting

- PU equipment

- Forming lines,

- Thermo-forming ovens,

- Post cured ovens for carbon fiber parts

- Wide range of presses with double mobile plates, sliding plates and foldable plates

- Hydraulic presses with hot plates to produce composite parts

- Auxiliar machinery for automated product lines and robotization

MEI's customers are leading international manufacturers worldwide.

References:

- Grupo Antolin

- Aciturri

- Autoneum

- Exide Technologies

- B/S/H

- Faurecia

- Valeo

- Adler Pelzer Group

- Treves

- The Autins Group

- Intier Automotive

- Borgers

- MSD

- Algontec