WHAT is P-DCPD?

P-DCPD is a material based on the reaction of DiCycloPentaDiene monomer.

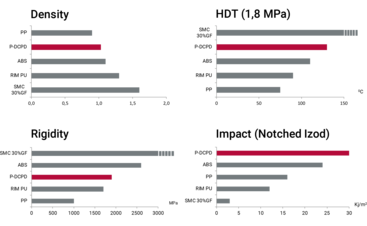

The material is an unfilled duroplastic material, which is characterized by very high impact resistance.

The material retains its high impact resistance even at extreme outside temperatures of - 40 to + 130 degrees Celsius.

WHY - USP's?

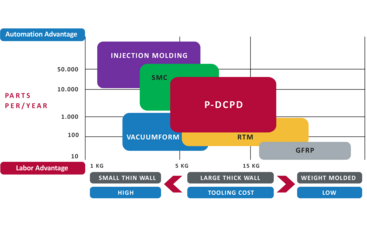

Our unique selling proposition (USP) is not only related to the material properties but also in its processing.

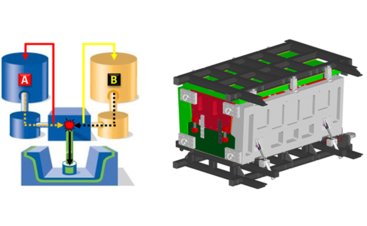

The production process offers great design freedom "Designer Friendly" for large and complex components.

The cycle time is on average 5 to 10 minutes, also possible to make in one tool multiple cavities, of different sizes and shapes.

The material is characterised by very high impact resistance.

The production process has a high repeatability, therefore it is CPK-compatible (process capability index).

The finished product shows excellent performance both at low and high temperatures ( - 40 / + 130 degrees Celsius).

FOR WHAT - which applications?

The large-area components manufactured in the P-DCPD process are used successfully, especially in applications in the agricultural construction machinery, truck and bus sectors.

The main applications are exterior trim and body parts.

Due to the excellent material properties, new markets (e.g. wind power industry) and new applications (e.g. electric charging stations) show great interest in P-DCPD.